Extrusion Tooling... on the Leading Edge of Technology

America's Most Innovative Plastic Extrusion Tooling Designer & Manufacturer

Guill is the leading Extrusion Tooling Designer & Manufacturer with nearly 60 years of experience. Our engineers specialize in plastic extrusion tooling design, utilizing the most advanced technology currently available. We draw on our years of experience to tailor tooling and die design for your industry, helping you increase efficiency and decrease production cost when operating your plastic extruder. From extruding PVC pipe to complex profile co-extrusion, we are committed to helping you produce the best end product possible.

Are Challenging Extrusion Projects Wasting Your Resources?

Solutions

We offer the most extensive line of extrusion tooling in the industry, providing you with many solutions.

Quality

Our extrusion and defense divisions share the same high standard of quality, producing tooling manufactured in the USA.

Efficiency

Our innovative tooling designs focus on providing less down time, so your production is at maximum capacity.

Our Sales Engineers Are Available to Help You

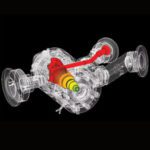

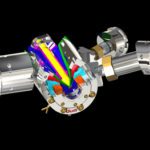

New Guill 900 Series Spiderless In-Line Die

Guill's Latest Design Ideal for Piping

Used by tube and pipe producers for larger diameter capabilities, this new pipe die is capable of providing a finished extrusion with OD from 2”-15”. It’s offered in 4140 steel or stainless with heat treating. Guill’s Spiderless Pipe Die design differentiates itself from a basket die by producing top quality high efficiency pipe extrusion.

The significance of the Guill Spiderless Pipe Die becomes evident when considering material savings. Guill’s Spiderless Pipe Die is now available to meet the needs of its customers as they consider all the factors needed to remain competitive in pipe production. e factors needed to remain competitive in pipe production. This

product was entirely conceived, designed, engineered, manufactured and tested at

Let's Get Started

Empowering you to do what you do BEST... Efficiently Effectively Profitably

Expertise, Excellence & Engineering Solutions

Your End Product is Our Priority

Our goal is for your customer to be happy and your line to run as smoothly and efficiently as possible. Our unique qualifications along with a skilled and talented staff provide you with partners to help make that happen.

Backed by Experience

Our longtime work across many plastics industries has resulted in many years of diverse extrusion experience. At Guill, we have mastered the tightest tolerances needed for producing everything from the smallest, most precise medical tubing to the largest, rugged under sea pipe and cable. As a result, we have the most extensive line of tooling in the industry and know how to solve the toughest challenges of the extrusion process.

Dedicated to Quality

We care about quality in everything we do, and we know you do too. Because our quality standards are driven by our defense division, our entire facility enjoys the benefits of maintaining rigorous standards across our extrusion and defense divisions. As a result, we have held ISO 9001:2015 along with other certifications to ensure excellence.

See How We Can Help You

Collaboration

From Concept through Engineering to Manufacturing

Guill excels in solving the most difficult challenges of the plastic extrusion process, all through our engineering and manufacturing expertise and commitment to excellence.

Contact our sales engineers today to discuss your latest projects.

Concept

Our team of sales engineers work closely with you to identify your needs.

Engineering

Our expert’s years of experience allow them to work with your custom needs to help improve the extrusion process. We specialize in precise plastic extrusion calculations, resulting in a keen sense of what tooling will help you do your best work.

Manufacturing

Your tooling will be manufactured following the same quality standards required by our government division.

Extrusion Expertise Is Here For You

Capabilities

Engineering

Designing and manufacturing outstanding custom extrusion tooling is our priority.

Manufacturing

We are committed to be the most cost efficient manufacturer while adhering to a continuous improvement quality management system.

Materials Testing

Your material's flow characteristics can be tested in-house, giving our engineers the information they need to design your tooling and ensure a perfect product is extruded.

Quality

Our extrusion and defense divisions share the same high standard of quality.

We're Hiring!

Click Here For Employment Opportunities at Guill

Did You Know

Upcoming Events

NPE 2024

5/06/24 – 5/10/24

Orange County Convention Center, Orlando, FL

Wire Expo 2024

6/11/24 – 6/12/24

1 Mohegan Sun Blvd, Uncasville, CT 06382

Extrusion Expo

11/13/24 – 11/14/24

Cleveland, OH

Your Extrusion Tooling Designer & Manufacturer

Contact us today to find out how we can help you optimize your extrusion process. Our Sales Engineers are happy to discuss your next project with you.