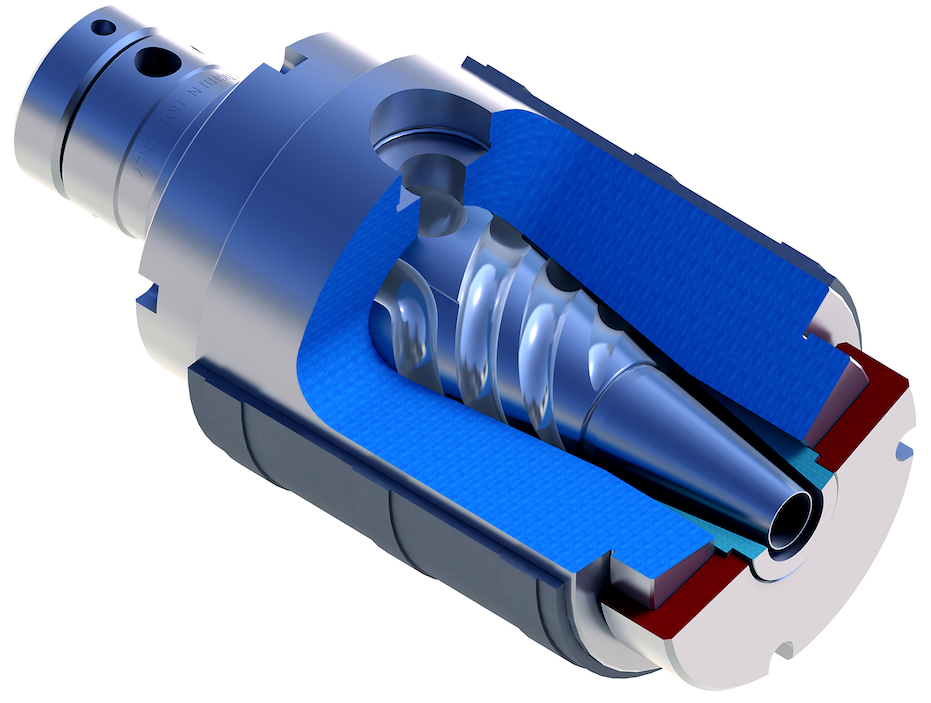

The Electronics industry requires extreme precision when manufacturing essential parts. Our Extrusion Tooling offers unmatched accuracy in the production of wire and cable, not matter the required gauge. Our multiple layer and stripping designs have been remarkably successful for controlling concentricity and wall thickness tolerances, providing significant material savings and increased product quality.

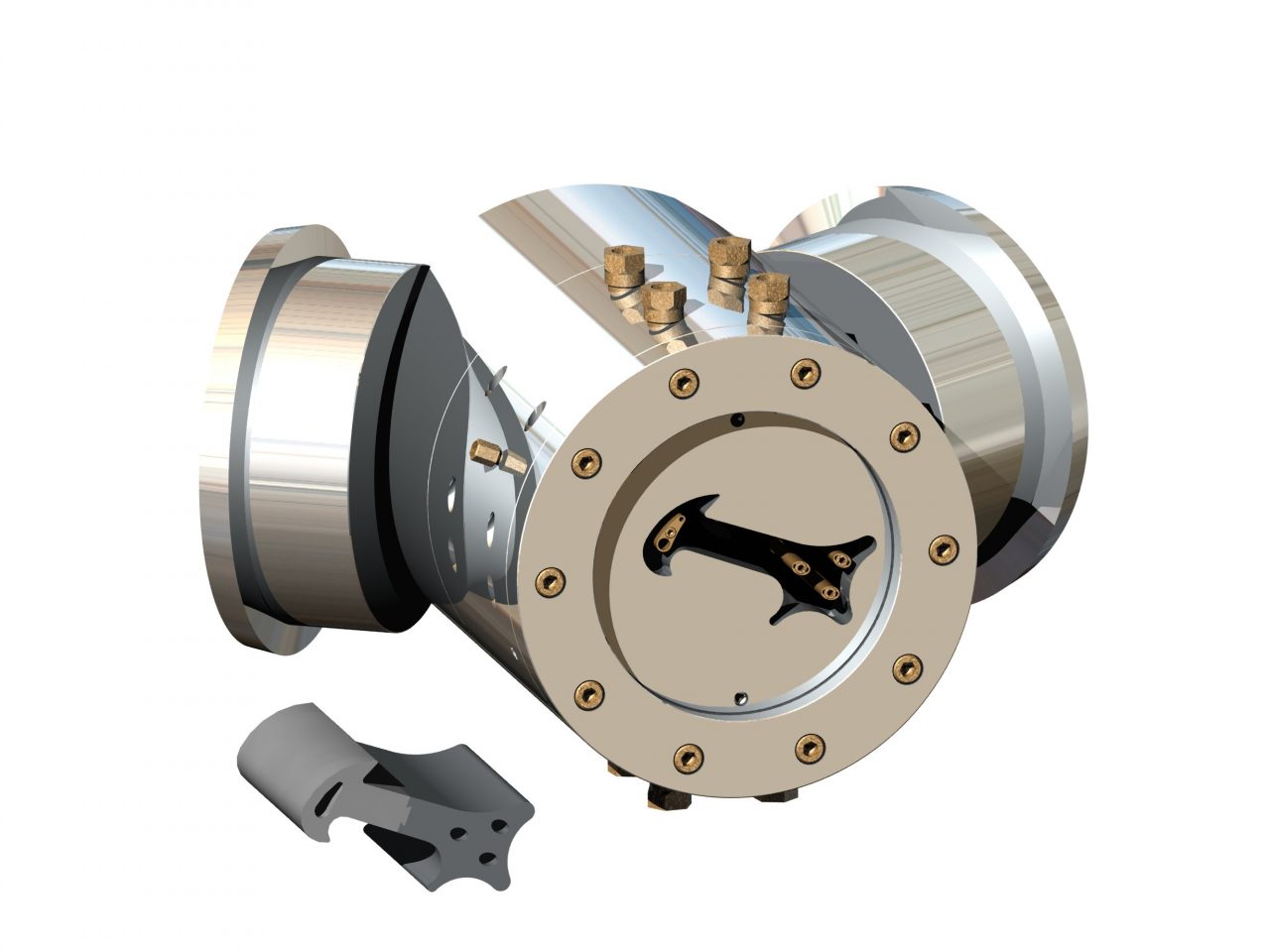

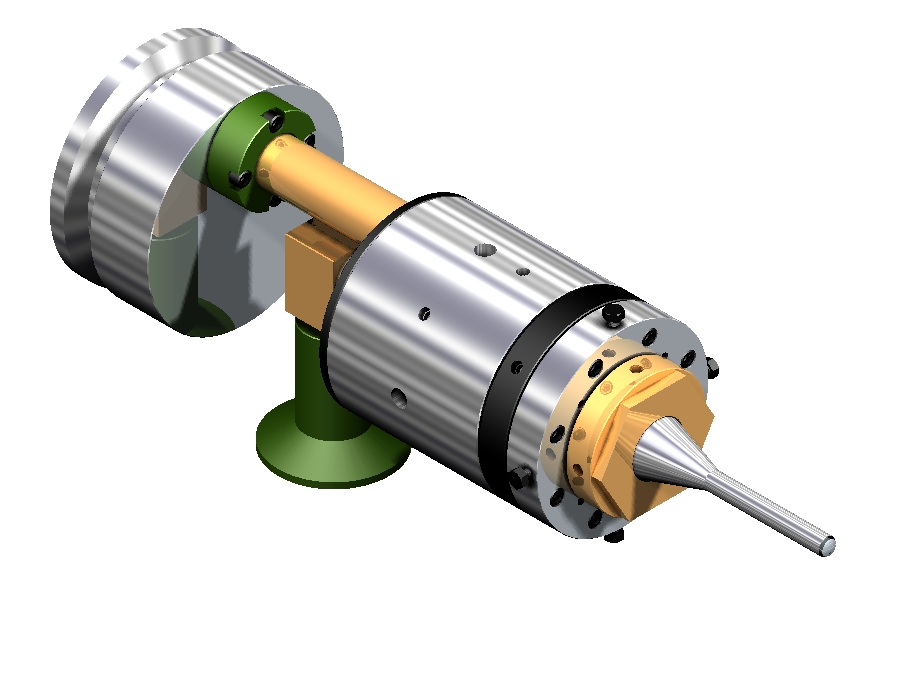

Automotive Parts

Whether you are manufacturing Automotive Hose, Brackets, Gaskets, Seals or other extruded parts, we have a full line of profile, rubber & silicone and corrugated extrusion tooling to help you produce an excellent end product.