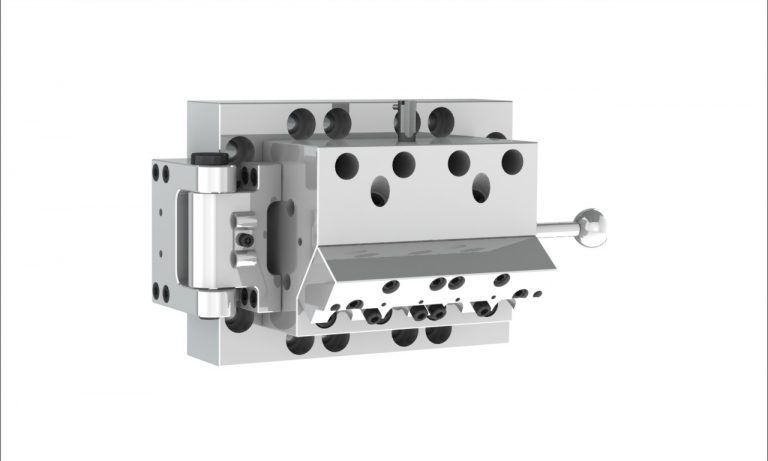

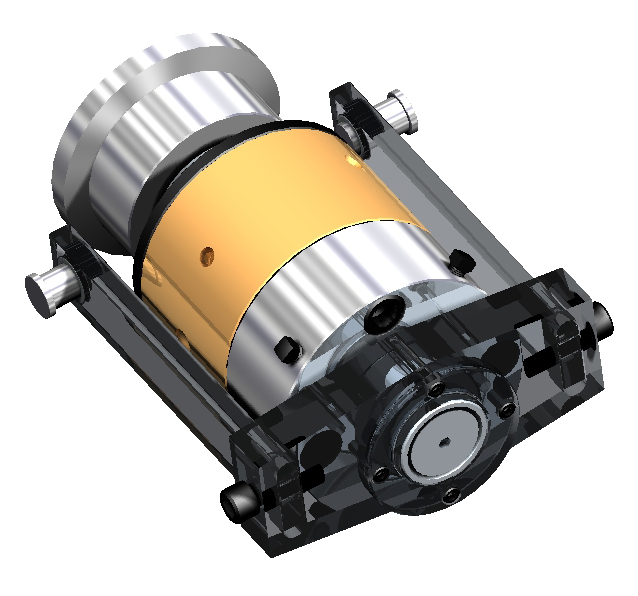

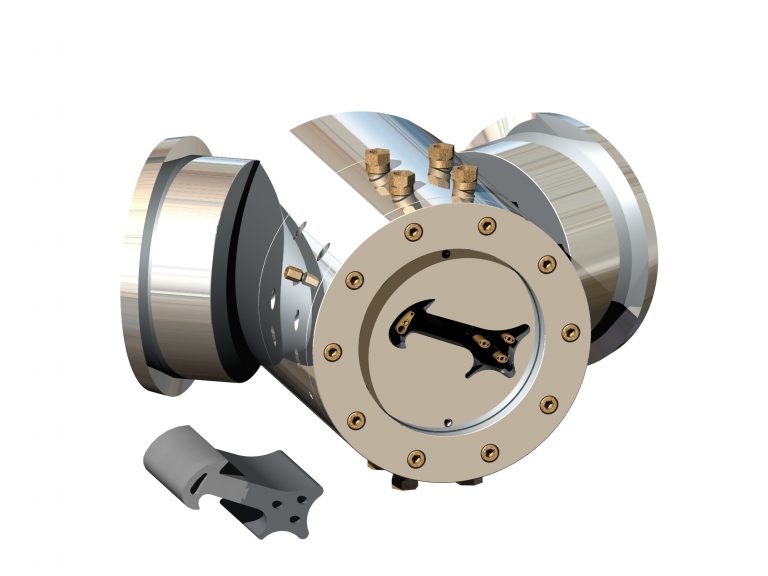

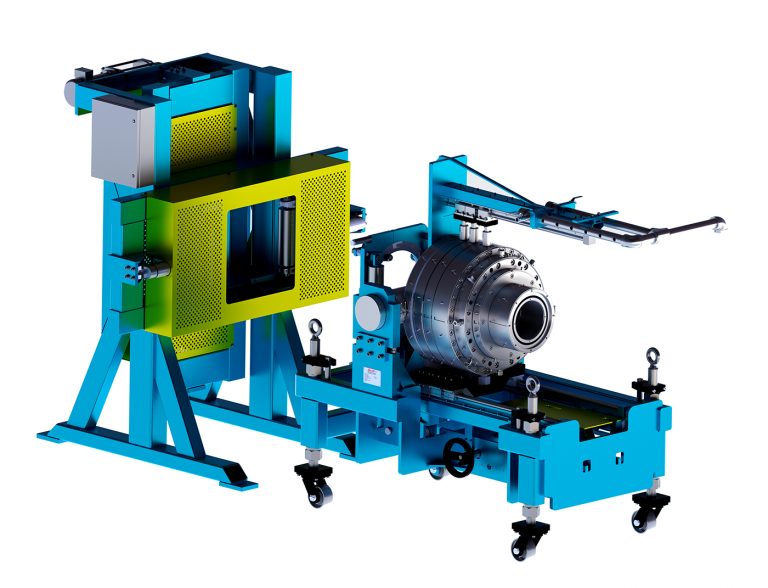

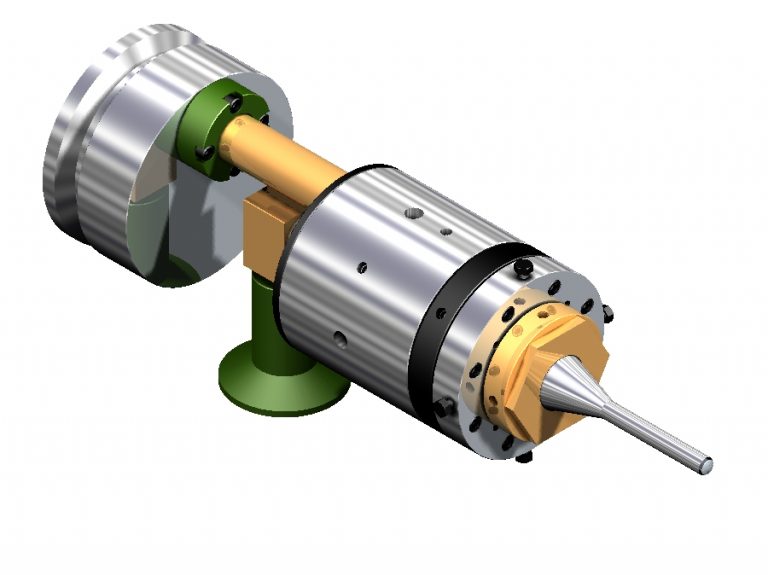

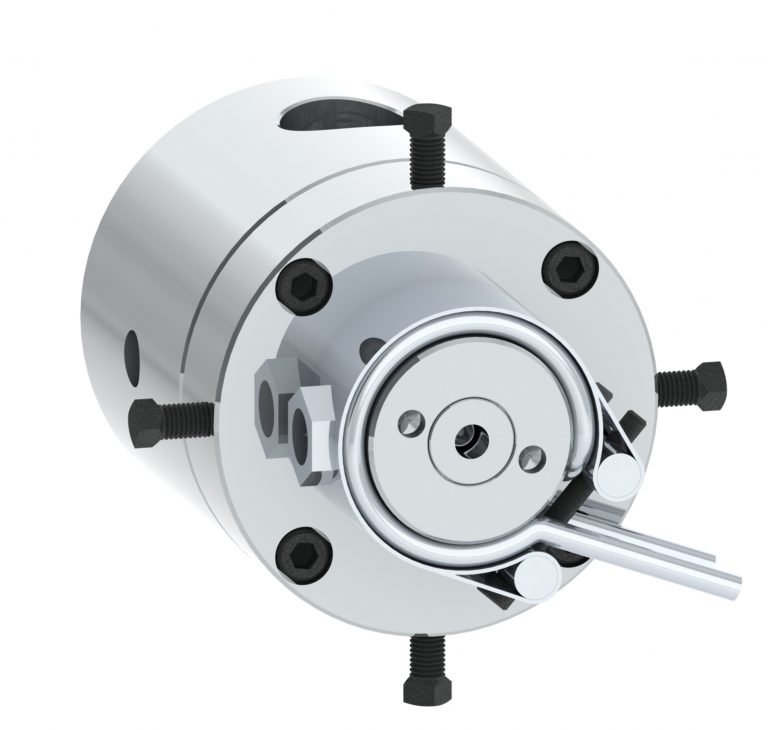

We offer in-line head tooling to manufacture a variety of products for many different industries. Simply identify the product type to find the tool most applicable to your manufacturing requirements.

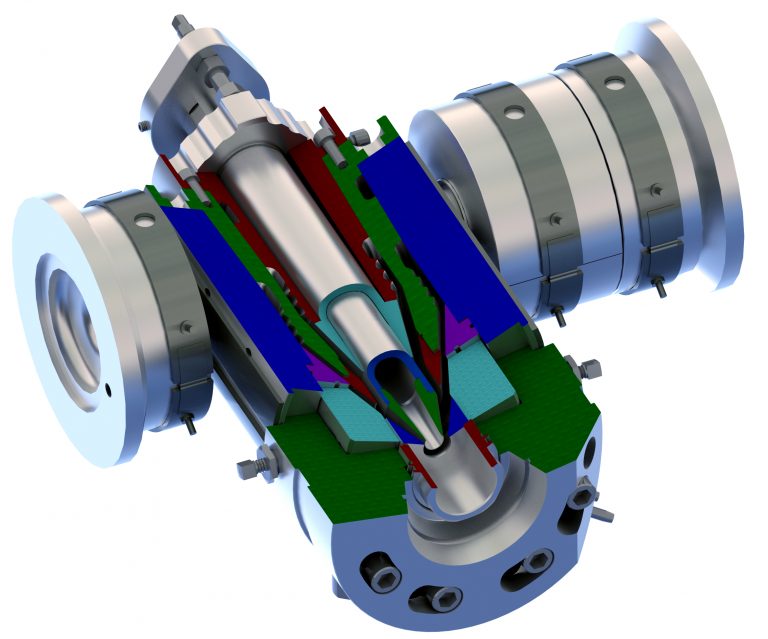

Our Inline heads use our FlexiSpiral™ deflector design to rotate the melt stream, continuing the mixing process and eliminating weld lines.