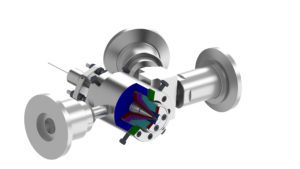

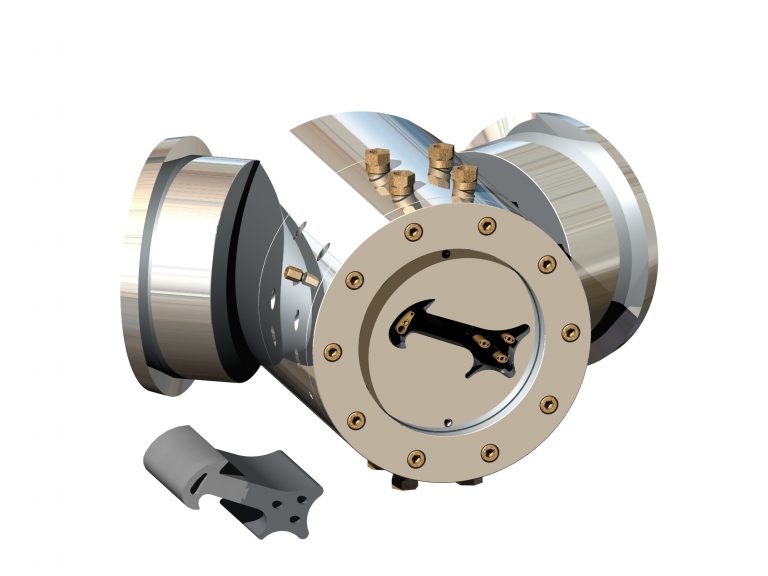

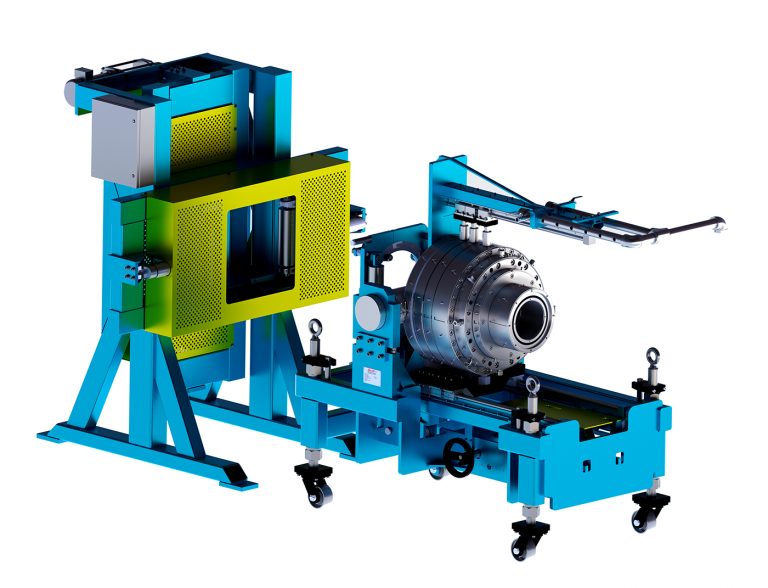

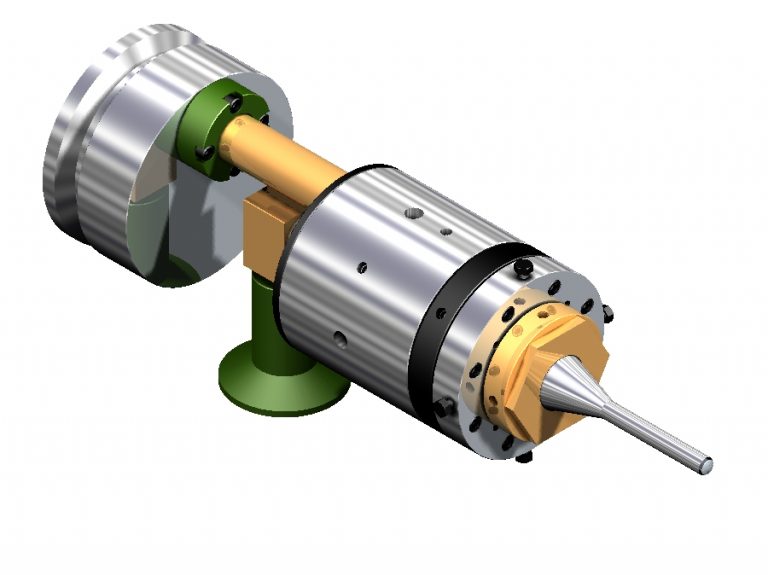

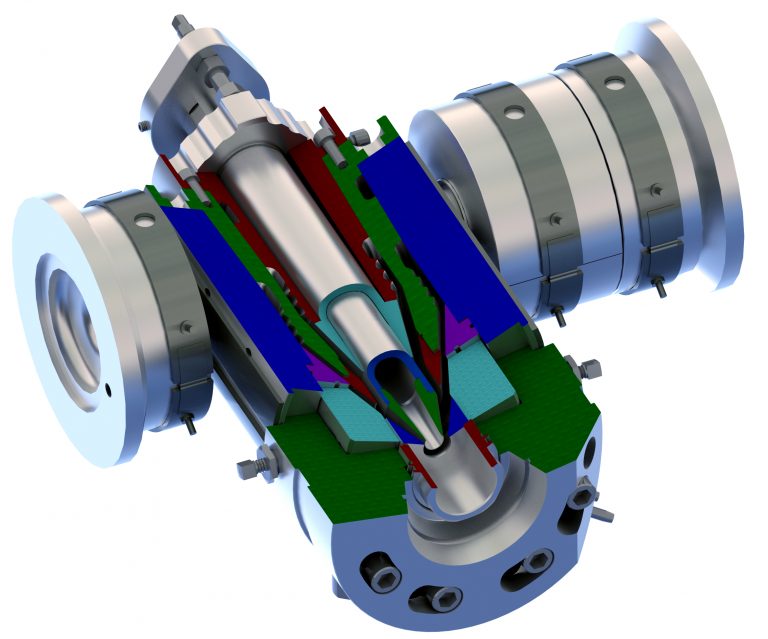

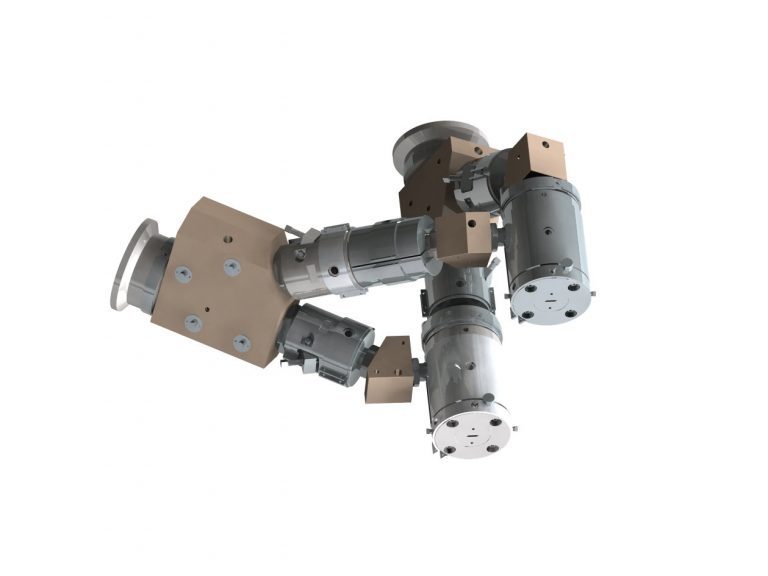

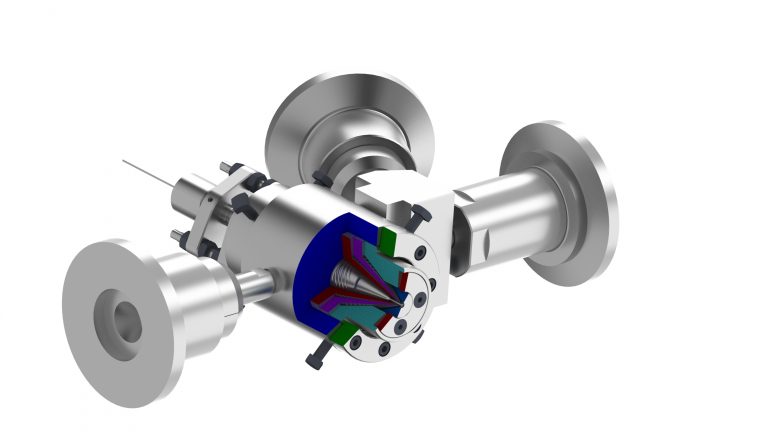

We manufacture all of our tooling to handle even the most significant challenges of the crosshead extrusion process. Our team of engineers offer decades of experience in crosshead design, and are committed to helping you find the right head and die for your extruder. At Guill, all our extrusion crossheads are crafted for precision and easy operation in mind, from wire extrusion to producing renewable PLA filament and other custom plastic end products.

Please take a look at our available line of tooling below for more information.