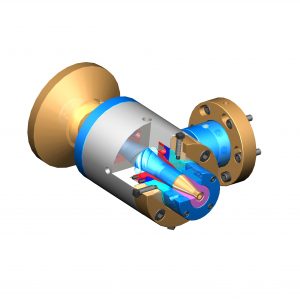

Balanced Flow Deflector

The Guill Balanced Flow Deflector is designed to distribute the material flow equally to the tip and die resulting in equal velocity of the melt stream. We’ve designed this deflector using Computational Fluid Dynamics (CFD) programs which allow us to identify inconsistent balance at the die exit giving us the