West Warwick, RI USA – Guill Tool & Engineering has introduced EquaFlow II™ — a new generation of its tooling for extruding wood and polymer compounds that provides even greater accuracy and more consistent product flow than its predecessor – and results in significant cost savings from reduced waste material.

“Guill offers much more than other tooling systems — particular flow analysis,” states Bill Conley, Guill sales manager. “We calculate the amount of material required throughout your profile and design the flow channels to meet these requirements. Once the tooling has been designed, we run the design through our flow analysis software to ensure that our calculations are accurate.”

For years, manufacturers of wood and polymer compounds — for such applications as decks, playgrounds, all-weather flooring, furniture and accessory items – have been plagued by wide tolerance variations, warping, twisting, voids, sagging at the product center, and having to run at reduced production speeds to accommodate uneven material distribution.

The EquaFlow II help resolve these problems, resulting in greater product consistency (reduced waste material), improved tolerance accuracy, and improved production speeds.

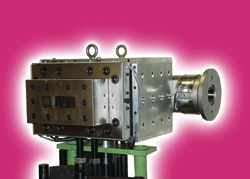

With the EquaFlow II system, material distribution and consistency are enhanced by a specially designed, patent-pending combined die and reservoir system – a first in the industry.

This revolutionary wood/polymer system includes a special co-extrusion capability that enables the simultaneous extrusion of multi-materials.

A dual output is also available, enabling one extruder to expand output by 40%-50% without the necessity of investing in additional extruders.

The new system is engineered for solid core, hollow core, single-layered and multi-layered wood composite and polymer applications. Overall the EquaFlow II measure 17 3/4″ length x 11 1/2″ high to produce a wood polymer profile combination in all popular sizes.

“With the EquaFlow II extrusion system, manufacturers can produce even more precise and consistent end products. In addition, customers save even more money from reduced material waste – even compared with the original EquaFlow series,” concludes Bill Conley.

Guill Tool also manufactures tips, dies, and breaker plates using state-of-the-art computerized CNC machining and EDM equipment.

Engineering services using the latest CAD systems are available for custom designing extrusion tooling products: crossheads, tips, clamps, flanges, air wipes, forming rolls, spiderless inline dies, dies, swing gates, breaker plates, special equipment and sizing dies.

Guill Tool received ISO certification in 1995. The first major extrusion tooling company to meet those international standards. The company has long been recognized as one of the leading established designers and manufacturers of custom extrusion tooling for types of applications including: wire, cable, fiber optics, medical tube, wood composites, automotive tube, plastic compounding, custom applications, rubber, profile, industrial pipe, hose & tube, blow molding, food and packaging.

The company also encourages and provides education and training for the extrusion industry with plastic and aluminum model heads, fully illustrated operating manuals for step-by-step assembly and disassembly, training videotapes, as well as classes on the care and cleaning of extrusion tooling.

Founded in Rhode Island in 1962 by A. Roger Guillemette, the company was established as a job shop supplying tips, dies, crossheads and replacement parts to the wire, cable or wire and cable, plastic and rubber industries in New England and eventually across the US and Canada.

For a free evaluation, technical product sheets, general information, or for the name of a representative in your area, please contact Guill Tool & Engineering Co., Inc. 10 Pike Street, West Warwick, RI 02893 (USA), Tel: (401) 828-7600, Fax: (401) 823-5310 or email: sales@guilltool.com.