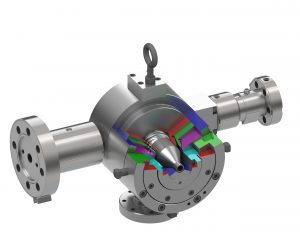

Crosshead with Emitter Cool Tube & Cart

Guill Tool & Engineering is a recognized leader in the Design and Manufacture of Plastic Extrusion Tooling

worldwide. Since 1962, Guill Tool & Engineering has supplied Extrusion Tooling for many Industries beginning

with Wire & Cable and expanding to Medical, Automotive, Hose & Pipe, Compounding, Packaging and Wood

Composite. Guill specialized in multiple layer extrusions having developed patented tool component features

for controlling layer tolerances and concentricity leading to material cost savings. All Guill products are

manufactured in the USA in an ISO: 9001 registered facility.

Challenge

A leading manufacturer of commercial and residential irrigation tubing came to Guill with a Crosshead

application that required precise placement and bonding of preformed emitters within the extruded tubing

without melting them. The challenge for Guill was to create a single head that can process either the low

cost ABA layer construction or single layer construction as well as allow for emitter insertion even though the

polymer and the emitters have significantly different temperature processing windows.

Solution

The engineering department at Guill designed a Crosshead that:

· Allows low cost material in ABA construction as well as single layer to both run in a single head

· Processes these materials with significantly different temperature processing windows with cool tube design

· Provides up-time with fast & easy changeover from co-extrusion to single layer

· Facilitates accurate placement and robust bonding of emitters

· Allows use of older production equipment with cool tube design

Outcome

The Crosshead is currently running with the customer’s production extrusion equipment and providing cost

benefit product that uses even more of the low cost recycled material than expected and meets all quality

requirements. This project also included a cart with benefits as seen by the customer including easy to perform

alignments, easy to execute tool changes, easy to complete changeover from co-extrusion to single layer, all in

a sure footed package. The removable cart swing gates allowed for easy storage to keep them free from

processing fluids. The adjustable height allowed for use at any of the existing extruders. And the thermal

isolation piece improved heat loss from the head to the cart.

This customer has become a key account for Guill Tool and this project has led to additional opportunities with

this valued customer. In addition, as we continue our partnership with this customer, we are collaborating on

the next generation design of this head to further increase the gains we have seen with this design.

Guill Tool & Engineering Co., Inc. is committed to meeting and exceeding the needs of our customers. The

requirements of ANSI/ASQC Q9001- 2004 International Standards (ISO: 9001) are communicated and

maintained at all levels of the company through training and internal audits. Every employee exhibits a high

degree of quality ownership in the products and customer service provided.